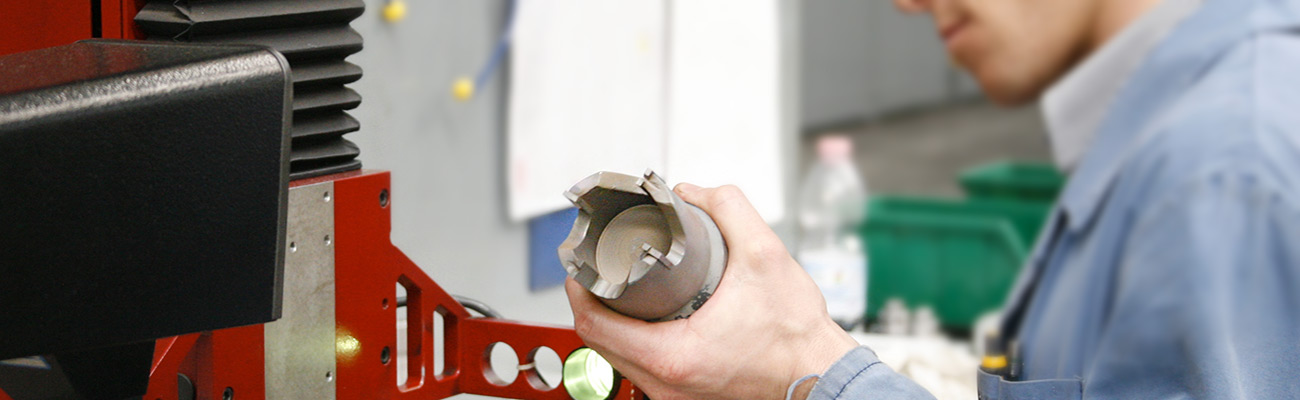

Tool Manufacturing

Brass is known for its high workability coefficients. This allows the use of tools with complex shapes, the use of which would be impractical or ineffective anyway on other materials. Anzolin Fernando & Con-Press, having gained decades of experience in the field and thanks to the know-how gained from its specialized technical staff, is able to realize fully all the tools necessary for machining of the most complex design forms and all systems workpiece surfaces used during processing in the car of the details themselves.

The use of plants to multiple axes allows the realization of the piece handling systems in a single setup without any limit of morphology. According to workloads in the company, the equipment needed to produce the items is made to realize by qualified external suppliers.

Machines Park

The site Anzolin Fernando & Con-Press S.p.A. in Arzignano (VI) is the seat of the machining department for chip removal which includes various types of machine tools, which differ in type, size and complexity of the product to be worked.

business machines is made up of over ten machine tools able to realize any type of piece. Thanks to the flexibility and high performance offered by the transfer and work centers used by the Anzolin Fernando & Con-Press S.p.A. it is possible to produce components, from the simplest to the most complex construction operations.

- Machines "transfer" with vice fixed for the production of products in three ways.

These machines, whose vices product locking do not rotate during the work cycle, can have from 5 to 18 units according to the considered model and allow to make medium / low difficulty machining, for considerable production levels.

- "transfer" machines with clamp and machining direction of 4-way.

This machine is an evolution of the previous one and has a total of & nbsp; 20 units. Also the quality is better, because the rotation of the machine in the terminal allows the machining of the fourth way, avoiding the transfer of workpiece. In this type of machine you can run both high processing degree of difficulty than in the previous type of machines described would be impossible to terminate them without several occasions and are suitable for high production levels.

-Machines "work center" with clamp rotation and processing of 6 streets.

This machine is designed to perform geometrically complex machining on six sides .

The machine management is carried out by means of the latest generation Fanuc CNC able to cope with more complex interpolation needs with the top numerical control of 16iMB range.

The machine is also equipped with an automatic tool change system comprising a rotating disk stock with 32 toolholders cells, the gripper arm with automatic locking and rotation group extraction cam.

This machine is suitable for high processing complexity of execution for medium-low production series.